Portable Bulk Material Storage for Varied Process Requirements

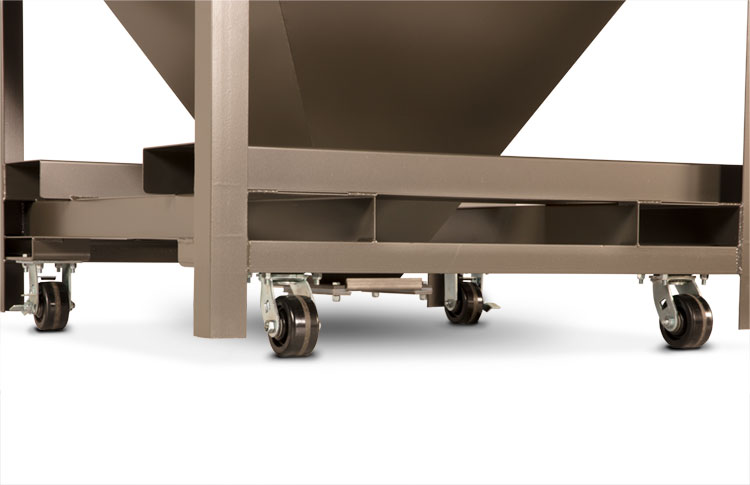

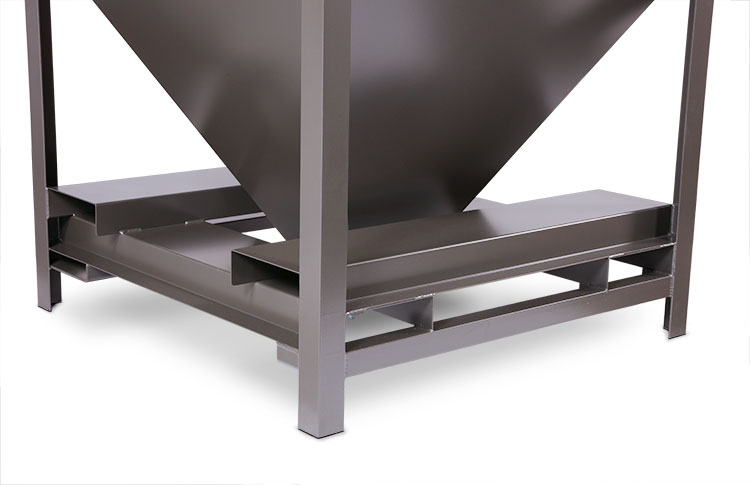

National Bulk Equipment mobile storage hoppers provide processing and production operations an efficient, durable material storage alternative to unstable, non-stacking, irregular-shaped bags, totes, and gaylords. NBE mobile storage hoppers stack easily to conserve floorspace; and are available with a variety of line interfacing methods to ensure reliable material supply to low- or medium-capacity lines. NBE mobile storage hoppers are designed and built to be process-critical assets, not disposable commodities.